競馬ファンの間でワイドは効率の良い買い方として知られており、初心者の方にもおすすめできる券種のひとつです。

しかし、ワイドの買い方がイマイチよくわからない、という方が多くいるようなので皆さんがワイドの買い方をマスターできるように回収率のあがる買い方から、やってはいけない買い方、ワイドの種類について解説していきます。

場が荒れそうだと予想するレースで買う事の多いワイドですが、その判断基準についても記述していくので、ぜひワイドを買う際の参考にしてください。

さらに!本当に勝てる競馬予想サイトはこちら!

おすすめの券種、ワイドの買い方

今回紹介するワイド(正式名称:拡大馬番号二連勝複式)は購入した2頭の組み合わせが、1着から3着に来れば的中(例:1着2着,1着3着,2着3着)となり、その名の通り的中範囲が広いのが特徴な券種です。

ただし、注意点として3着が同着の場合には外れとなってしまうので注意しましょう。

では、ワイドの買い方について説明していきます。

主な買い方としては、1着から3着に入る2頭の馬を予想し、購入した2頭が3着以内に来れば的中になるので、最大で3通りの組み合わせが的中する馬券になっています。

皆さんは馬連や枠連を購入し、選んだ馬2頭が穴馬に抜かれ2着3着でゴールした悔しい経験はありませんか?

馬連や枠連と比較すると平均配当は低くなりますが、そんな場合でもワイドなら的中となるので的中率が高く効率が良いと言われています。

逆に言うとワイドの買い方としては、「場が荒れるな」と予想されるレースで購入するのがおすすめです。

その理由として、「1番人気2番人気が絶対に来るだろう」と予想できるレースで人気順通りの馬が来てしまうと配当はとても低くなり、ワイドで購入するメリットが無くなるためです。

そのような状況では馬連か、1番人気か2番人気どちらが先に来るかわからないなという場合には枠連で買うことをおすすめします。

3連複や馬連との違いを知ってワイドで狙おう!

上記でワイドの買い方を説明しましたが、同じ複系馬券の3連複や馬連と似ている点があるのをお気づきでしょうか?

初心者の方や、イマイチ理解しきれない方は混同しやすい券種なので、それらの違いと買い方について詳しく説明していきます。

3連複、馬連とワイドの主な違いとして、1着2着が来れば的中なのはもちろんですが、1着3着、2着3着でも的中となり、さらに順不同でもOKという点がワイドの特徴です。

簡単にまとめたので見てみましょう。

・ワイド: 1着から3着のどこかに入る2頭を当てる馬券

・3連複: 1着から3着に入る3頭すべてを当てる馬券

・馬連:1着、2着に入る2頭を当てる馬券

上記の馬券は全て順不同なため少々似ていますが、ワイドの特徴は選んだ馬が2着3着でも良い、という点です。

以下の例をご覧ください。

例:1着⑦、2着③、3着⑤の場合 3連複は⑦-③-⑤で当たり、馬連は⑦-③で当たり、ワイドの場合⑦-③はもちろんですが、1着⑦3着⑤、2着⑦3着⑤でも当たりになります。

また、ボックスで購入した場合③-⑤や⑦-⑤でも当たり(順不同)となります。

基本的な払戻金は3連複、馬連の方が高い傾向にありますが、その配当は人気によって大きく変わってきます。

例として1番人気2番人気で的中させた馬連よりも、2番人気10番人気でワイドを当てたほうが高配当になり、経験上、人気上位の馬連は4倍から5倍でワイドの人気馬+穴馬の場合は20倍前後になります。

つまり、人気順の通りに組み合わせると配当は低く、人気の低い馬を絡めることで高配当になるということです。

払戻金だけで言えば、3連複や3連単の方が高配当の期待はできますが、的中率はそのぶん低くなるので安定重視でコツコツ稼ぎたい方はワイドをおすすめします。

ワイドで複数的中させる買い方

ワイドのメリットとして1レースで複数の的中ができるという点もあります。

先ほど記述したワイドの的中として1着2着,1着3着,2着3着この3通り全て的中となります。

例:⑤⑧⑩という3頭をワイドボックスで購入した場合、馬券の組み合わせとして⑤-⑧、⑤-⑩、⑧-⑩の3通りとなり、⑤⑧⑩の全てがワンツースリーでゴールした場合、全てが的中になるのです。

しかし、人気上位の3頭を選んでこの買い方をしても配当は低くなる事が予想されるので、おすすめする買い方としては、「人気馬+穴馬2頭」が配当も良く、資金は少ないけど競馬を楽しみたい場面で、非常に良い買い方と言えます。

また、より的中率を上げたい場合の買い方として、「人気馬2頭+穴馬複数」のボックスもおすすめです。

1着2着は堅いけど、この穴馬も来そうだなと予想できる場合は、ぜひ挑戦してみてください!

やってはいけないワイドの買い方

ここまでワイドの良い点を紹介してきましたが、やってはいけない買い方も存在します。

ワイドは3連単と比較して買いやすい券種なので、初心者の方がやりがちな買い目を増やし過ぎてしまうことはNGです。

その理由として、ワイドは買い目を増やせば増やすほど的中率は向上しますが、平均配当の低いワイドで買い目を増やしてしまうと、不要な馬券まで購入してしまう事となり、トリガミになる可能性が高くなるのです。

的中させたいがために点数を多く買ってしまい、当たったけどトリガミになってしまっては意味がありません。

配当金が購入金額を下回らないためにも、点数は多くても4点、5点がおすすめです。

買い目を増やすことで長期的に見れば結果的に損してしまう可能性が高くなるので、レース選びは慎重に行ったうえでワイドを購入しましょう。

ワイドの買い方の種類を学ぼう

基本的なワイドの買い方として、3着までに入る2頭を選ぶという買い方ですが、その他にワイドの買い方として「ながし」「ボックス」「フォーメーション」などがあります。

競馬は中央競馬、地方競馬合わせて年間で約19,000ものレースが開催されているので、それぞれのレースや出走馬に合わせて馬券選びや買い方も変えることで、より競馬を楽しめるでしょう。

では、それぞれの買い方について紹介していきます。

ボックス編

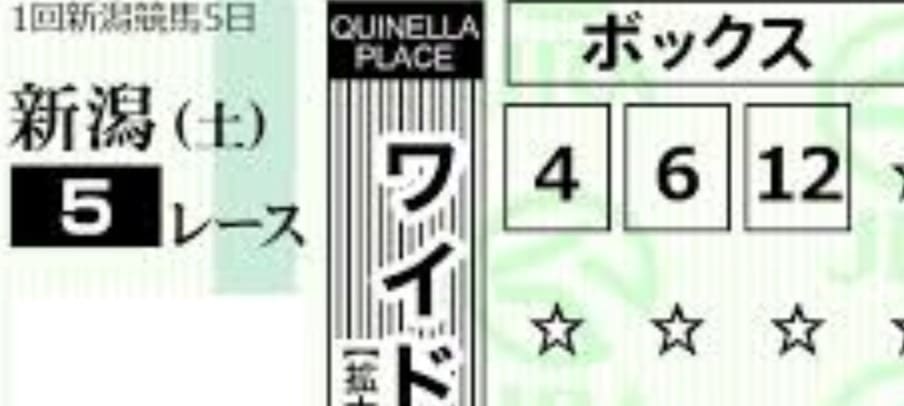

「ボックス」は選んだ馬の組み合わせを全て購入する方法です。

ながしと違う点として、来るだろうなと予想できる馬が複数いる場合に全て買うことで、どれが3着以内に来ても当たるという買い方です。

例:③⑤⑦を購入した場合の買い目は③-⑤,③‐⑦,⑤-⑦の3点となります。

デメリットとして、このボックスで買い目を増やしすぎてしまうと損してしまう可能性も増えるので注意しましょう。

フォーメーション編

ワイドのフォーメーションを組む場合は1通りではなく、何を重視するかによって変わります。

的中率を重視したい、高配当を得たい、そのどっちも狙いたい、など、人によってさまざまですが、安定的に勝てるというワイドの最大の特徴を生かしてフォーメーションを組むのが良いでしょう。

具体的に説明すると、人気馬1頭に穴馬1頭を絡めた馬券を購入することで、人気馬の的中率と穴馬の回収率のメリット同士でつなげることができるのです。

もちろん全てのレースでこのパターンを適用させるわけではなく、この組み合わせを軸に考えることでワイドとしての券種を楽しめると言えます。

まとめ

今回は安定して勝てるおすすめの券種、ワイドの買い方を紹介しましたが、いかがでしたでしょうか?

今までワイドについてよく分からないまま購入していた方や、これまで遠慮していた方も今回の記事を参考にワイドを実際に購入してマスターすることで、今後の競馬予想に幅を持たせることができます。

ワイドについて紹介してある外部サイトでは「競馬を制すワイド馬券の買い方&最も儲かる3つの理由を紹介!」が参考になります。ワイドを極めれば、三連複や三連単の予想へと可能性は広がるのでもっと競馬がおもしろくなりますよね。

ぜひ、ワイドの買い方をマスターしてチャレンジしてみてください。